ChatGPT said: The advantages of working with 10:9 Design Embroidery for branding

Everything About Screen Printing: A Comprehensive Guide to Its Advantages and Applications

Screen printing has an abundant background and serves many markets today. Its benefits, including vibrant colors and resilience, make it an appealing selection for bulk production. Numerous makers and services utilize this approach for various applications, from fashion to promotional things. Understanding the screen printing process is important for those wanting to access its potential. What complies with is an exploration of its advantages and methods that might change imaginative undertakings.

The Background of Screen Printing

The advancement of screen printing is a fascinating trip that traces back to ancient people. The method can be linked to the Chinese, that established a form of stenciling as early as the Song Dynasty (960-1279 ADVERTISEMENT) using silk and natural inks. By the 18th century, screen printing made its way to Europe, where craftsmens embraced and adjusted the method for textile design.

In the 20th century, screen printing got popularity in the USA, specifically with the increase of commercial printing and marketing. Musicians like Andy Warhol made use of the approach, raising it to an art form. The intro of artificial inks and mesh fabrics better revolutionized the process, making it more versatile and reliable. Today, screen printing is widely made use of in numerous industries, from textiles to signage, showcasing its long-lasting relevance and adaptability via the ages.

Advantages of Screen Printing

Screen printing offers countless advantages that make it a recommended choice for lots of organizations and artists. One substantial advantage is its convenience; it can be used to numerous materials such as textiles, steels, and plastics, enabling a vast array of applications. In addition, screen printing provides sharp images and dynamic colors, ensuring high-grade outcomes that stand apart.

Applications of Screen Printing

Applications of screen printing are varied, spanning various markets and functions. This versatile technique is commonly made use of in fabrics, permitting dynamic layouts on garments, hats, and accessories. In the advertising items market, companies commonly count on screen printing to develop personalized things such as tote, canteen, and banners, boosting brand name presence.

Additionally, screen printing finds use in electronic devices, where it is used to apply conductive inks on circuit card. The automotive market likewise gains from this approach, using it for attractive aspects and safety and security labels. The art community embraces screen printing for producing limited edition art work and posters, supplying musicians a means to replicate their job with precision. The packaging sector utilizes screen more info printing for product labeling, making certain that branding is both long lasting and attractive. Overall, screen printing's versatility makes it an essential tool across numerous areas.

The Screen Printing Process

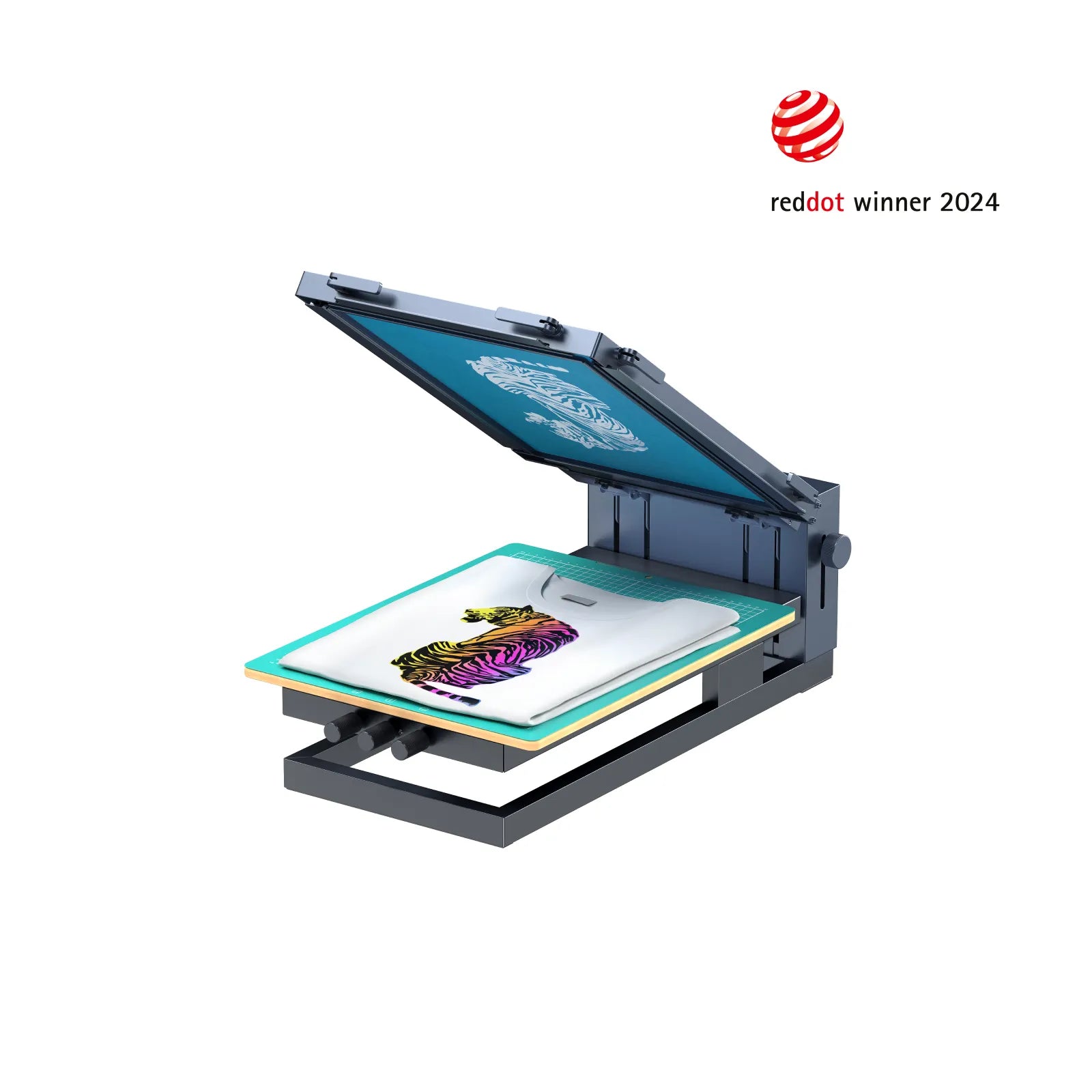

Understanding the screen printing procedure includes numerous vital actions that transform a layout into a substantial item. Initially, an image is produced and after that moved onto a display, which is generally made from a fine mesh material. A pattern is used, allowing just certain areas of the screen to pass ink. Next, the screen is positioned over the substratum, whether it be textile, paper, or another material.

A squeegee is after that utilized to press ink through the open locations of the stencil onto the substrate. This procedure can be repeated for several colors, needing specific positioning for every layer. After printing, the item usually goes through a treating process to establish the ink, ensuring longevity and vibrancy. This systematic method makes screen printing a reliable and versatile method for generating premium designs on a variety of materials, accommodating both creative and commercial needs.

Tips for Starting With Screen Printing

Beginning on a display printing journey can be both tough and interesting for novices. To guarantee a smooth introduction, it is crucial to start with the ideal tools. Buying a standard screen printing set can supply important devices without frustrating costs. Newbies ought to also familiarize themselves with the screen printing process, including preparing displays, mixing inks, and correct printing techniques.

Connecting with other screen printers, either online or in neighborhood workshops, can provide support and motivation. Lastly, maintaining a tidy workspace and arranging materials can simplify the printing process, making it more reliable and enjoyable. With patience and practice, newbies can find success on the planet of screen printing

Regularly Asked Questions

What Products Can Be Made Use Of for Screen Printing?

Screen printing can use different materials, including cotton, polyester, plastic, and paper. In addition, inks such as water-based, plastisol, and discharge are typically employed, enabling diverse applications throughout fabrics, product packaging, and promotional items.

How Lengthy Does Screen Printing Last on Clothes?

Screen printing can last several years on garments, depending on factors like ink quality, textile kind, and treatment guidelines. Correct washing and dealing with considerably boost the sturdiness, guaranteeing the design stays vibrant with time.

Can Screen Printing Be Done in the house?

Yes, screen printing can be done in your home. With the ideal devices and materials, individuals can develop personalized layouts on various garments, allowing for individual expression and imagination in their tasks without requiring expert solutions.

What Is the Expense of Establishing a Display Printing Service?

Setting up a display printing company commonly sets you back in between $2,000 and $10,000, depending upon tools top quality, materials, and work space. Added costs consist of marketing, utilities, and continuous supplies, which can significantly affect total financial investment.

How Do I Clean Screen Printing Screens?

To cleanse screen printing screens, one need to make use of a solvent to remove ink, followed by a pressure washer or pipe to get rid of deposit. Finally, a gentle scrub with a brush guarantees that displays continue to be in excellent condition.

In the 20th century, screen printing obtained popularity in the United States, particularly with the rise of business printing and marketing. Additionally, screen printing locates use in electronics, where it is used to apply conductive inks on circuit boards. Understanding the screen printing procedure involves several crucial steps that change a layout right into a concrete item - 10:9 Design Embroidery. Screen printing can last numerous years on garments, depending on variables like ink top quality, material kind, and care guidelines. To clean screen printing screens, one should use a solvent to remove ink, complied with by a pressure washing machine or pipe to remove residue